This guide is a intended to be an introduction to the process of building a race car out of a 2CV road car. The process is geared more towards the ‘Club’ Class. ‘Eco’ class requires even fewer modifications.

This guide is a intended to be an introduction to the process of building a race car out of a 2CV road car. The process is geared more towards the ‘Club’ Class. ‘Eco’ class requires even fewer modifications.

Car:

Citroen 2CV road cars that are in need of some work or have failed their MOTs can be picked up on eBay, Gumtree or other online sites for a couple of hundred pounds. Perhaps £500 or so. Given these cars will be 30 years old or so by now, they will probably need some welding and some new panels, but that’s no big obstacle as the repair panels are cheaply and readily available, and some welding will be needed anyway for things like the roll cage.

If the thought of welding is a bit daunting, then there are plenty of specialists out there who will make repairs to your body shell or help you fit a cage. They can be found on the suppliers page.

Roll cage:

While most processes involved in converting a road car to a race car can be handled by the DIY mechanic, this one usually requires some specialist tooling, or the services of a company that specialises in fabricating cages. There are a few racing teams that can handle the fabrication of a cage, or can point you to a company that will do the job. Occasionally a pre-made cage comes up for sale, but these are rare – you can fit one of these by removing the floor of a shell. New cages can be fabricated in situ. A solid metal roof needs to be fitted on top of the cage between the front hoop and the main hoop. This is in addition to the roof of the car.

Chassis:

Chassis:

Needs to be a standard Citroen chassis, or one of two types of aftermarket chassis: a Frome racing chassis, or SLC racing chassis. Of all these, only the standard Citroen and SLC racing items can be bought ‘new’. The Frome racing chassis is no longer made.

Roof:

The fabric roof needs to be removed and replaced with a sheet of metal – usually aluminium, incorporating the back window.

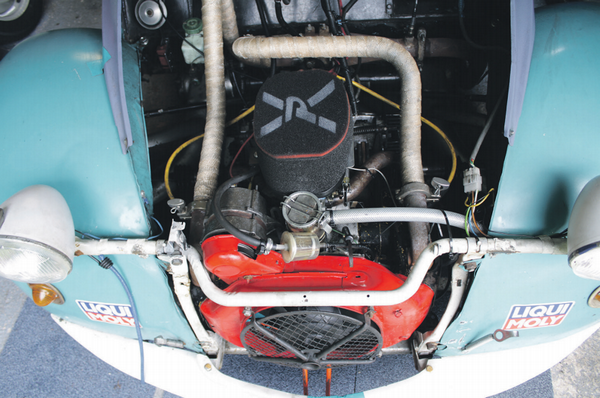

Engine:

Quite a lot can be done to the engine, but realistically not all the things listed in the regs need to be done to build a competitive engine. The crank must remain standard, and the camshaft replaced by the official club camshaft, available from Kent Cams. Pistons should be replaced with 9.0:1 compression pistons. After that, valves can be replaced by special racing versions, and valve springs replaced with uprated versions.  All these parts except the camshaft are available from 2CV parts specialists. The flywheel can be lightened, which often is regarded as a specialist job, but if you have a lathe it can be a job for the DIYer. A “racing spec” Lumenition electronic ignition system can be fitted (some still use points!), and the timing can be advanced to up to 33 degrees.

All these parts except the camshaft are available from 2CV parts specialists. The flywheel can be lightened, which often is regarded as a specialist job, but if you have a lathe it can be a job for the DIYer. A “racing spec” Lumenition electronic ignition system can be fitted (some still use points!), and the timing can be advanced to up to 33 degrees.

Carb/filter:

Most teams nowadays run the Weber DMTL carburettor, as it’s an approved alternative to the standard Solex. It’s not mandatory however.

Exhaust:

Exhaust:

This is ‘free’ after the manifold stubs, so basically anything goes here. Most replace the standard pea-shooter and torpedo with a larger bore 2-into-1 system, and a pre-designed system is available from some teams.

Gearbox:

Not a lot needs to be done with the gearbox. A lot of racers will stake the gearbox and some may replace bearings, but this is mostly unnecessary. Many run with totally standard ‘boxes. The gearstick in the cockpit can be extended, which is useful as most seats are mounted further back than standard roadgoing seats.

Brakes:

Brakes:

The standard 2CV braking system is usually good enough for racing. Some teams use uprated disc pads, and it is permitted to fit heat sinks to the calipers to aid cooling.

Suspension general:

The suspension is normally lowered by a considerable amount for racing. The approximate ride heights are 170-175mm front, and 195-200mm rear, measured from floor to sill. Springs are uprated – standard springs are around 1000 lbs, and racing springs are usually 2500-4000 lbs. Dampers are usually replaced by off-the-shelf Gaz or Avo units (adjustable), but some racers still use standard non-adjustable dampers with thicker oil.

Suspension arms:

Suspension arms:

Due to the lowering of the suspension, the caster (steering inclination) of the front arms needs to be changed, otherwise the steering will be very stiff. This is accomplished by cutting the end off the front suspension arms where the hub attaches, and re-welding it back on at a different angle. At the same time, some camber is usually added. Most people at this point add the ‘belgian arm’ modification, which is an additional strenghening member which attaches the top part of the hub to the arm. Often another suspension arm cut in half is used for this member, coupled with a spherical joint or similar. Arms can also be strengthened, and this is usually a good idea for the rear arms, which have to be bent by considerable force to get additional camber into them. Cutting and re-welding of the arms is usually regarded as a bit of a specialist job due to the accuracy involved, and there are teams which will do this for you. The Belgian arm modification can be a DIY process, but your welding should be up to a high standard!

Bodywork:

Bodywork:

Most 2CV body panels are kept standard. However, the door glass and rear window should be changed to 4mm polycarbonate plastic sheet as a safety precaution, and also to reduce weight. The front screen must be laminate glass. A lot of racers make the panels ‘quick release’ by adding some form of alternative fastners. For example on the rear wings to make them more easily removable for changing tyres, etc. The front wings are usually kept attached to the light bar, and the valence panels are kept attached to the wings, and the light bar is made to be quick-release, in such a way that the wings, valences and light bar come away as one unit. This makes the process of changing engines quicker.

Electrics:

Electrics:

For 24hr purposes most teams fit more powerful bulbs and additional spotlights to the light bar. Dashboards are usually ‘home grown’ with aluminium panels and additional gauges and switchgear. A lot of teams run an air/fuel meter as a means of tuning the Weber carburettor for different conditions. A rev counter is usually considered essential, and a lot of cars run with temperature sensors.

Safety:

Safety:

As well as the roll cage, there are a few other safety systems that need to be installed. First is a competition seat; this needs to be well mounted and the floor reinforced, as floor panels typically have a lot of flex. Safety belts also need similar reinforcing where they are fixed to the floor/chassis. A plumbed-in fire extinguisher needs to be installed too – this can be manually activated using pull-cords, but must discharge into the engine bay and the cockpit. Boot and bonnet must have additional securing straps.

Consult our suppliers page for more information on available suppliers and guidelines on cost: click here